The organic fertilizer industry has experienced substantial growth in recent years, driven by the rising demand for sustainable agricultural practices. Consequently, several manufacturers have developed organic fertilizer pellet machines, each offering unique advantages. This article highlights the strengths of different brands in the market, assisting potential buyers in making informed decisions.

RICHI Machinery

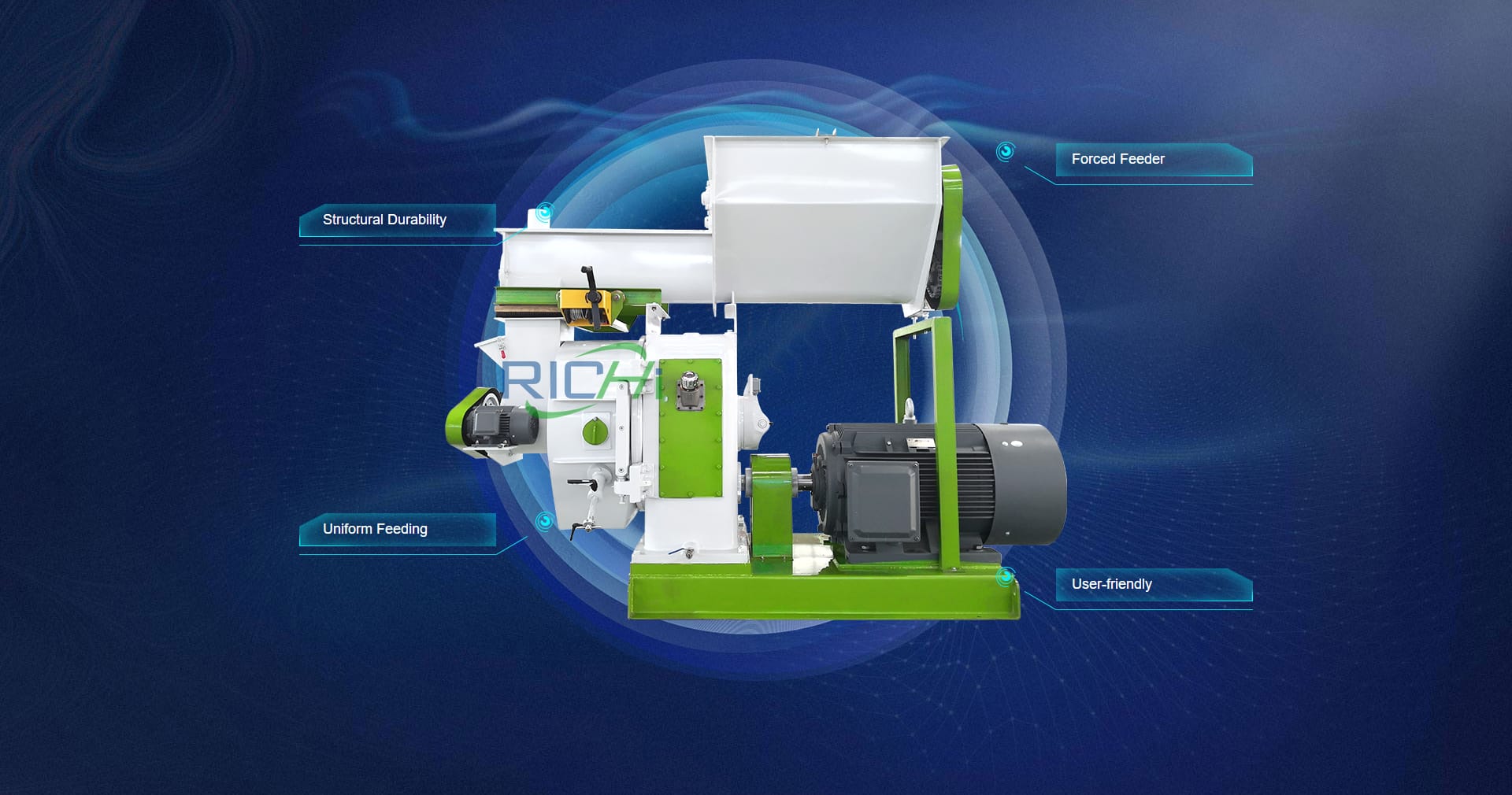

RICHI Machinery has established itself as a prominent brand in the organic fertilizer pellet machine sector, offering several key advantages:

- High Pelletizing Rate: RICHI’s machines achieve a pelletizing rate exceeding 90%, ensuring efficient production.

- Low Failure Rate: Known for their reliability, RICHI machines experience minimal downtime, contributing to consistent output.

- Minimal Maintenance: RICHI designs emphasize ease of maintenance, lowering operational costs and boosting overall efficiency.

- Versatility: These machines can process a variety of organic materials, including animal manure, urban food waste, and crop residues.

- Advanced Technology: RICHI incorporates microbial fermentation technology, facilitating room-temperature processing without the need for a drying room.

Shunxin Machinery

Shunxin Machinery provides a range of organic fertilizer pellet machines with distinct advantages:

- Customization Options: They offer tailored services to customize machines based on specific customer needs.

- Variety of Models: Shunxin features different types of granulators, including drum granulators, disk granulators, and two-in-one fertilizer granulators.

- Polishing Capability: Their polishing machines enhance the appearance and uniformity of the pellets.

- Comprehensive Solutions: Shunxin offers complete organic fertilizer production lines, providing end-to-end solutions for manufacturers.

Tongda Heavy Industry Machinery

Tongda Heavy Industry Machinery specializes in biomass pellet machines that can also be adapted for organic fertilizer production:

- Cost-Effective Solutions: Tongda is recognized for competitive pricing without compromising quality.

- Research-Driven Approach: With over thirty years of research experience, their machines integrate advanced technologies and efficient designs.

- Diverse Product Range: They offer various pelletizers, including double roller granulators and flat die pelletizers.

- Expertise in Biomass: Their proficiency in biomass processing is beneficial for organic fertilizer production, particularly with plant-based materials.

GEMCO Energy Machinery

GEMCO Energy Machinery focuses on pellet machines suitable for both biomass and organic fertilizer production:

- Energy Efficiency: GEMCO machines are designed to conserve energy, reducing operational costs.

- Durability: Their machines are robustly constructed, ensuring a long service life.

- Versatility: GEMCO machines can process a wide range of organic materials, making them applicable for various uses.

- Global Support: With a strong international presence, GEMCO provides reliable after-sales support worldwide.

Zhengzhou Fusmar Machinery

Zhengzhou Fusmar Machinery is known for its innovative organic fertilizer equipment:

- Innovative Designs: Fusmar continuously updates its designs to incorporate the latest technological advancements.

- High Production Capacity: Their machines efficiently handle large-scale production needs.

- User-Friendly Operation: Fusmar prioritizes ease of use, making their machines accessible to operators with different experience levels.

- Comprehensive Quality Control: They implement stringent quality control measures throughout the manufacturing process, ensuring consistent performance.

Henan Kingman M&E Complete Plant

Henan Kingman is recognized for its holistic approach to organic fertilizer production:

- Integrated Solutions: They provide complete organic fertilizer production lines, ensuring compatibility among different components.

- Advanced Control Systems: Kingman machines feature sophisticated control systems for precise operation and monitoring.

- Customized Production Plans: They offer tailored production plans based on specific customer needs and raw material characteristics.

- Continuous Innovation: Kingman invests heavily in R&D, regularly introducing new features and improvements.

Anyang GEMCO Energy Machinery

Anyang GEMCO, a subsidiary of GEMCO Energy, offers distinct advantages of its own:

- Specialized Organic Models: They provide models specifically designed for organic fertilizer production, optimizing performance for these materials.

- Compact Designs: Their machines often feature space-saving designs, ideal for operations with limited floor space.

- High-Temperature Resistance: Anyang GEMCO machines can withstand high temperatures typically encountered in organic fertilizer production.

- Eco-Friendly Focus: Their designs emphasize environmental considerations, minimizing emissions and energy consumption.

Zhengzhou Tianci Heavy Industry Machinery

Zhengzhou Tianci has built a strong reputation for its heavy-duty organic fertilizer equipment:

- Robust Construction: Their machines are engineered for continuous, high-volume production.

- Adaptability: Tianci machines can be easily adjusted to accommodate various raw materials and production requirements.

- Advanced Cooling Systems: They feature efficient cooling mechanisms, essential for maintaining pellet quality in large-scale production.

- Comprehensive Training: Tianci offers extensive operator training programs, ensuring customers can maximize their machines’ potential.

Conclusion

The organic fertilizer pellet machine market presents a diverse array of options, each with distinct advantages. RICHI Machinery is known for its high efficiency and advanced technology, while Shunxin excels in customization. Tongda provides cost-effective solutions backed by extensive biomass processing experience. GEMCO and Anyang GEMCO focus on energy efficiency and durability, while Fusmar and Kingman emphasize innovative designs and comprehensive solutions. Zhengzhou Tianci caters to heavy-duty production needs with robust, adaptable machines.

When selecting an organic fertilizer pellet machine, it’s crucial to consider factors such as production capacity, types of raw materials to be processed, available space, budget, and specific operational features. By understanding the strengths of each brand, you can make an informed decision that aligns with your organic fertilizer production requirements.

Ultimately, the right choice will hinge on matching these brand advantages with your specific production goals, operational scale, and long-term business objectives within the organic fertilizer industry.