When setting up a wood pellet plant, it’s crucial to understand the various raw materials needed for efficient and sustainable production. Here’s a detailed look at the main types of materials that can be used:

Wood Residues from Forestry and Wood Processing Industries:

- Sawdust: A common byproduct from sawmills.

- Wood Shavings: Typically sourced from planing mills.

- Wood Chips: Often produced during the processing of logs.

- Bark: Can be collected from debarking operations.

- Twigs: Small branches and other forestry debris.

- Wood Dust: Fine particles from sanding and cutting processes.

- Waste Wood: Offcuts and remnants from wood processing and wood-based panel industries.

Agricultural Residues and Crop Wastes:

- Crop Straws: Including wheat, rice, maize, and cotton straw.

- Peanut Shells: A byproduct from peanut processing.

- Rice Husks: Generated during rice milling.

- Corn Stalks: Leftover stalks from corn harvesting.

- Bagasse: The fibrous residue from sugarcane processing.

- Grass and Alfalfa: Harvested for their fibrous content.

- Leaves: Collected during agricultural clean-up.

- Empty Fruit Bunches (EFB): Residues from the oil palm industry.

Related post: https://www.richipelletmachine.com/how-to-start-a-wood-pellet-business/

Other Biomass Materials:

- Waste Paper: Recycled paper products.

- Household Garbage: Combustible fractions sorted from general waste.

Key Requirements for Raw Materials:

- Moisture Content: Ideally between 14-20%, with around 12% being optimal.

- Size: Should be less than 5mm, or smaller than the pellet size.

- Binding Agents: Typically not needed, as the natural lignin in biomass acts as a binder.

Preprocessing Steps:

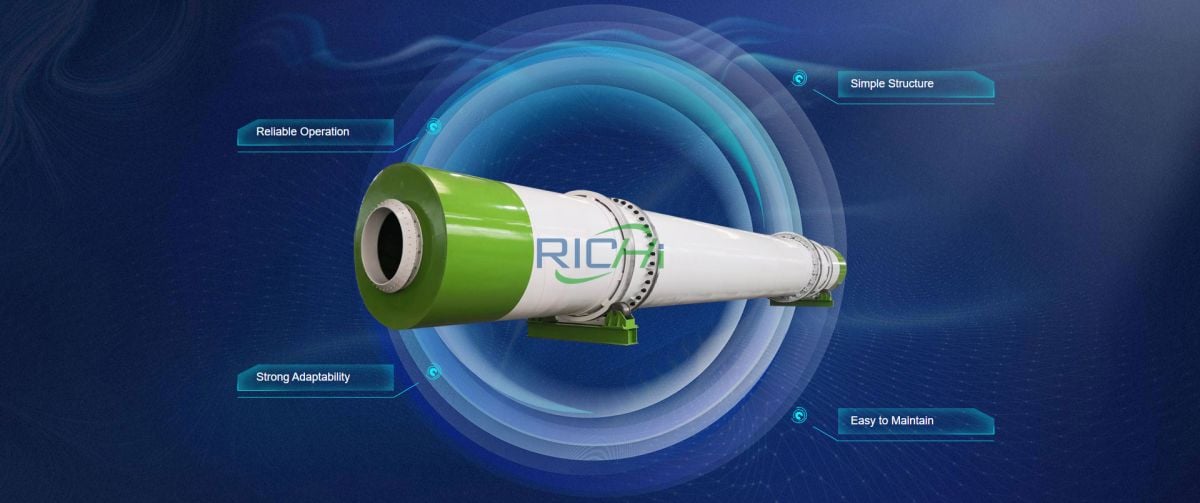

- Drying: To achieve the desired moisture content.

- Size Reduction: Using hammer mills, chippers, or crushers to get the raw material to the right size.

- Mixing: Sometimes different materials are blended to achieve the best pelletizing properties.

Wood pellet plants can effectively utilize a diverse range of biomass feedstocks from forestry, agriculture, and other industries. This versatility not only supports resource optimization but also promotes the sustainable production of wood pellets, contributing to the renewable energy sector.