Introduction

Organic fertilizer production lines vary widely based on raw materials, production processes, product forms, scale, and intended use. As the global push for sustainable farming intensifies, farmers and agri-businesses increasingly seek tailored solutions to convert agricultural waste into valuable organic fertilizer products. This article explores different types of organic fertilizer production lines, their design differences, application scenarios, advantages, and how to choose the most suitable type for specific agricultural or commercial needs.

1. Classification of Organic Fertilizer Production Lines

Organic fertilizer production lines can be broadly classified into the following categories based on output form, technology used, and raw material source:

A. By Product Form

- Powder Organic Fertilizer Production Line

- Granular Organic Fertilizer Production Line

- Liquid Organic Fertilizer Production Line

B. By Production Technology

- Composting-based Production Line

- Fermentation Tank-based Production Line

- Bio-organic Fertilizer Line with Microbial Inoculants

C. By Material Source

- Animal Manure Fertilizer Line (Chicken, Cow, Pig)

- Crop Straw/Residue Fertilizer Line

- Food Waste Organic Fertilizer Line

- Municipal Solid Waste Fertilizer Line

2. Powder Organic Fertilizer Production Line

Overview:

This is the simplest and most cost-effective type of organic fertilizer line. It processes composted organic material into powder form without granulation.

Key Equipment:

- Compost Turner

- Semi-wet Material Crusher

- Rotary Drum Screening Machine

- Packing Machine

Advantages:

- Low investment cost

- Fewer machines

- Suitable for small-scale operations or startup farms

Application Scenarios:

- Local farm use

- Small community-based composting projects

- Precursor step before granulation in large plants (Related post:4T/H Organic Fertilizer Manufacturing Plant In Netherlands)

3. Granular Organic Fertilizer Production Line

Overview:

Designed to produce uniform, high-quality granules with better storage stability and ease of application.

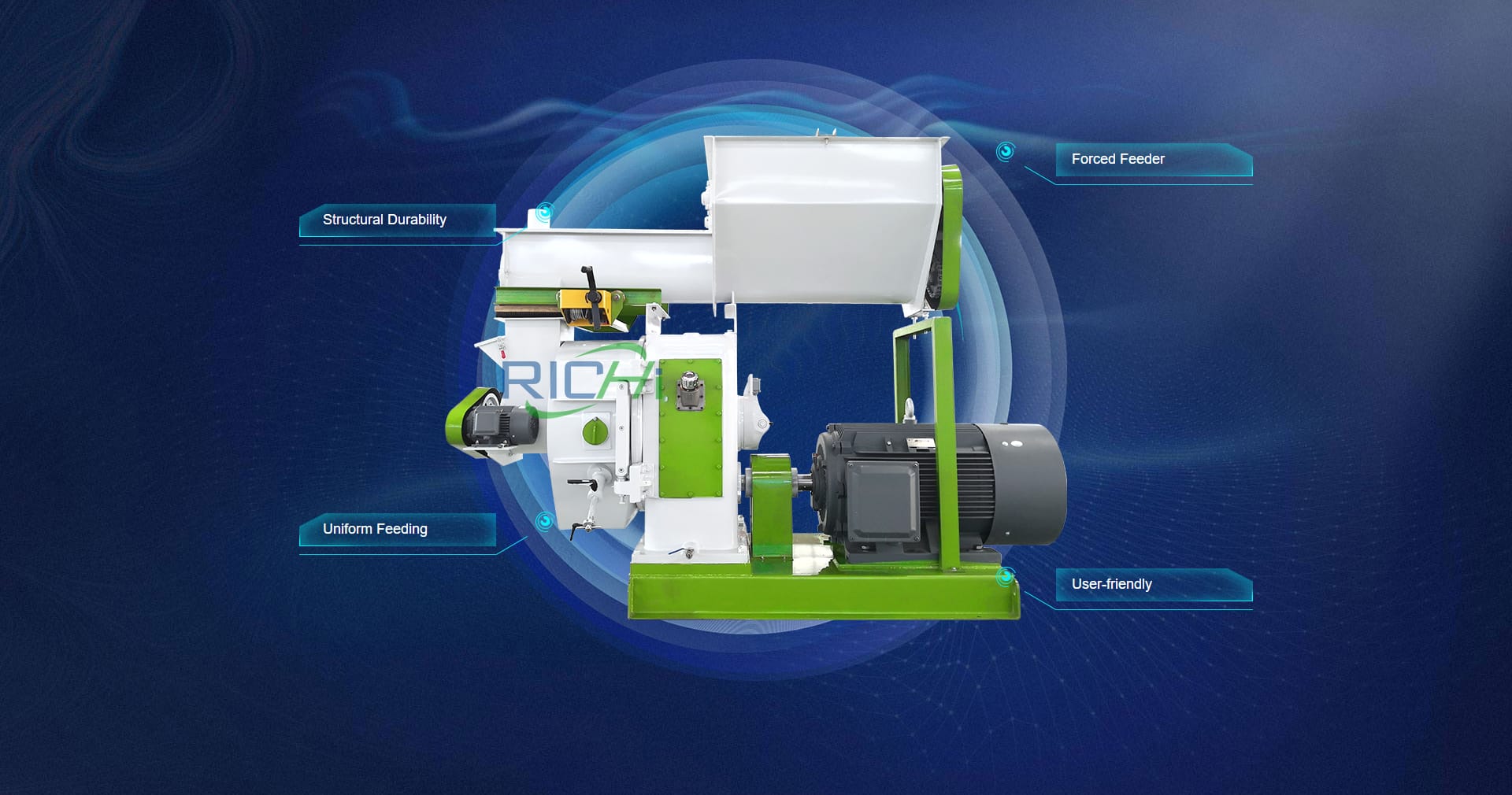

Main Equipment:

- Compost Turner

- Crusher

- Horizontal or Vertical Mixer

- Granulator (disc, drum, or new type organic)

- Dryer and Cooler

- Screening Machine

- Coating Machine (optional)

- Packaging Machine

Advantages:

- Higher commercial value

- Easier handling, transportation, and application

- Greater consumer acceptance

Application Scenarios:

- Commercial organic fertilizer factories

- Export-focused enterprises

- Companies serving industrial agriculture clients

4. Liquid Organic Fertilizer Production Line

Overview:

This line produces nutrient-rich liquid fertilizer, which is particularly effective for foliar feeding and fertigation.

Equipment Required:

- Fermentation tank or bioreactor

- Filtration system

- Mixing and dilution system

- Storage tank

- Liquid packing machine

Advantages:

- Fast nutrient absorption

- Suitable for high-value crops

- Allows for micronutrient and microbial enrichment

Application Scenarios:

- Greenhouse farming

- Fruit orchards

- Hydroponics and precision agriculture

5. Bio-Organic Fertilizer Line with Microbial Inoculants

Overview:

These production lines integrate beneficial microorganisms into organic fertilizers, improving soil microbial health and plant disease resistance.

Key Process Features:

- Composting with microbial inoculants

- Controlled fermentation conditions

- Low-temperature drying to preserve microbial viability

Application Scenarios:

- Organic-certified farms

- Agroforestry projects

- Soil restoration programs

6. Animal Manure-Based Fertilizer Lines

Types:

- Chicken manure fertilizer line

- Cow dung fertilizer line

- Pig manure fertilizer line

Considerations:

- Different manures vary in moisture, nitrogen, and pathogen load

- Pre-treatment (e.g., solid-liquid separation, pathogen elimination) is often required

Benefits:

- Turns livestock waste into valuable product

- Reduces farm pollution and odors

Common Features:

- Compost turners for aerobic composting

- Fermentation tank alternatives in cold regions

- Granulation and packaging systems

7. Agricultural Waste and Straw-Based Fertilizer Lines

Overview: Utilizes crop residues (corn stalks, wheat straw, rice husks) and green waste as main raw material.

Challenges:

- High C/N ratio requiring nitrogen supplementation (e.g., manure or urea)

- Longer fermentation times

Solution:

- Use of microbial inoculants to speed up decomposition

- Proper shredding and moisture control

Best Used For:

- Eco-parks

- Rural agricultural cooperatives

- Crop rotation support systems

8. Food Waste and Municipal Organic Waste Fertilizer Lines

Overview: Designed to process biodegradable kitchen waste, market waste, or municipal organic matter.

Special Requirements:

- Sorting system to remove plastics/metals

- Pasteurization or sterilization to kill pathogens

- Advanced odor control and leachate collection

Key Technologies:

- Enclosed fermentation systems

- Biofilters and deodorization units

- Automated batching and mixing

Best Suited For:

- Urban waste recycling centers

- Municipal governments

- Circular economy pilot projects

9. Fermentation System Types and Their Impact

Different fermentation methods affect the structure and cost of the production line:

- Windrow Composting: Low-cost, requires land and manual turning or windrow turners.

- Groove Composting: More mechanized, saves space, good for larger operations.

- Fermentation Tanks: High-tech solution, good for cold climates and urban areas. (Related post: fertilizer granulator machine)

10. Choosing the Right Type of Organic Fertilizer Production Line

Factors to consider:

| Factor | Influence |

|---|---|

| Raw Material | Dictates pre-treatment needs |

| Product Type | Affects marketability and consumer use |

| Production Capacity | Influences equipment size and investment |

| Local Regulations | May require specific treatment methods |

| Budget | Determines extent of automation and plant scale |

| Climate and Location | Impacts fermentation method selection |

11. Case Example: Integrated Manure and Straw Fertilizer Plant

- Location: Vietnam

- Raw Materials: Chicken manure + rice straw

- Product: Bio-organic granulated fertilizer

- Daily Output: 30 tons

- Process: Windrow composting → Crushing → Mixing → New type granulation → Drying → Cooling → Screening → Packing

- Special Features: Smart PLC control and odor control biofilter

12. Benefits of Specialized Production Lines

- Higher Operational Efficiency: Tailored processes reduce waste and energy use

- Improved Product Quality: Consistency in nutrient content and form

- Regulatory Compliance: Easier to meet hygiene and environmental standards

- Competitive Advantage: Unique products meet niche market needs (e.g., eco-fertilizers, organic-certified input)

Conclusion

There is no one-size-fits-all solution in organic fertilizer production. From small-scale powdered fertilizer lines for local farms to high-tech bio-organic granule production lines for export markets, each type has its own merits and application. The key is to match the technology and design with the raw material availability, target product form, and market demand. As organic farming continues to grow, more specialized and integrated production lines will shape the future of sustainable agriculture.