Introduction

In the modern agricultural landscape, the demand for high-quality organic fertilizers has been steadily on the rise. Organic fertilizers play a crucial role in maintaining soil fertility, improving soil structure, and enhancing crop yields while minimizing environmental impacts. The process of producing organic fertilizers involves several steps, and one of the key stages is granulation. This is where the organic fertilizer pelletizer comes into play. The organic fertilizer pelletizer is a specialized piece of equipment designed to transform organic raw materials into uniform, granulated fertilizers, which offer numerous advantages over traditional powder fertilizers. This article aims to provide a comprehensive introduction to the organic fertilizer pelletizer, covering its working principles, types, applications, and benefits.

Working Principles of Organic Fertilizer Pelletizers

Compression Pelletization

One of the most common working principles employed in organic fertilizer pellet machines is compression pelletization. In this method, the organic raw materials, which may include compost, manure, peat, and various organic additives, are fed into the pelletizer. The pelletizer is equipped with a set of rollers and dies. The rollers apply pressure to the raw materials, forcing them through the die holes. As the materials pass through the die, they are shaped into pellets. The size and shape of the pellets are determined by the design of the die holes. Compression pelletizers are highly efficient in producing dense and durable pellets, which are less likely to break during handling and transportation.

Extrusion Pelletization

Extrusion pelletization is another widely used principle in organic fertilizer pelletizers. In this process, the organic raw materials are first mixed and conditioned to the appropriate moisture content. Then, they are fed into an extruder. The extruder uses a screw mechanism to push the materials through a die plate. The die plate has multiple holes of a specific size and shape. As the materials are forced through the die, they are extruded into long strands. These strands are then cut into pellets of the desired length using a cutting device. Extrusion pelletizers are known for their ability to handle a wide range of raw materials and produce pellets with a relatively smooth surface.

Disc Pelletization

Disc pelletizers operate on a different principle. They consist of a rotating disc, which is inclined at a certain angle. The organic raw materials, along with a binding agent if necessary, are fed onto the rotating disc. As the disc rotates, the materials are tossed and tumbled. During this process, the materials gradually agglomerate and form pellets. The size of the pellets can be adjusted by controlling factors such as the rotation speed of the disc, the feed rate of the raw materials, and the moisture content. Disc pelletizers are relatively simple in design and are suitable for small to medium-scale production of organic fertilizers.

Types of Organic Fertilizer Pelletizers

Flat Die Pelletizers

Flat die pelletizers are a popular type of compression pelletizer. They are characterized by a flat die plate, which has a series of holes drilled in it. The rollers are mounted above the die plate and rotate against the surface of the die. As the organic raw materials are fed between the rollers and the die, they are compressed and forced through the die holes to form pellets. Flat die pelletizers are known for their high production efficiency and the ability to produce pellets with a consistent shape and size. They are suitable for both small and large-scale organic fertilizer production.

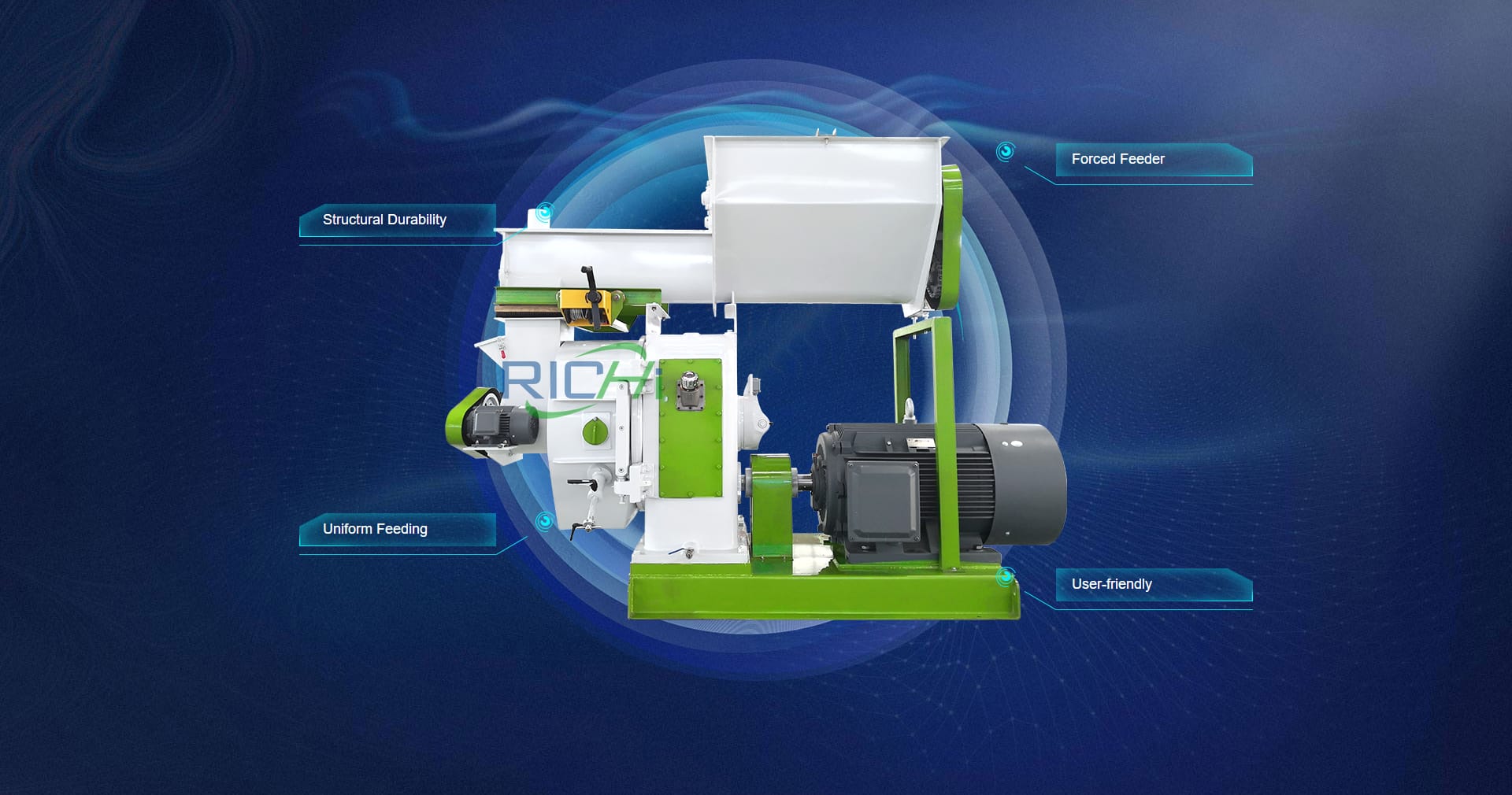

Ring Die Pelletizers

Ring die pelletizers are another type of compression pelletizer. In this design, the die is in the form of a ring. The rollers are located inside the ring die and rotate against the inner surface of the die. The organic raw materials are fed into the space between the rollers and the die, and the pressure exerted by the rollers forces the materials through the die holes. Ring die pelletizers are capable of handling high production volumes and are often used in large commercial organic fertilizer manufacturing plants. They can produce pellets with a high density and strength.

Drum Pelletizers

Drum pelletizers are a type of disc pelletizer with a drum-shaped rotating unit. The organic raw materials are fed into the rotating drum, which is lined with a non-stick material. As the drum rotates, the materials are tumbled and gradually form pellets. Drum pelletizers are relatively simple and cost-effective. They are suitable for producing organic fertilizer pellets in small to medium quantities and are often used in local or on-farm production facilities. (Related post:Organic Fertilizer Production Line)

Applications of Organic Fertilizer Pelletizers

Agriculture

In the agricultural sector, organic fertilizer pellets produced by pelletizers are widely used. These pellets can be applied directly to the soil as a slow-release fertilizer. The granulated form allows for more uniform distribution of nutrients in the soil, ensuring that plants receive a steady supply of essential elements. Organic fertilizer pellets are particularly beneficial for crops such as vegetables, fruits, grains, and flowers. They help improve soil fertility, enhance root development, and increase crop yields. Additionally, the use of organic fertilizer pellets reduces the risk of nutrient runoff, which can have negative impacts on water quality.

Horticulture

In horticulture, organic fertilizer pelletizers also play a significant role. Nurseries, greenhouses, and home gardens often use organic fertilizer pellets to provide plants with the necessary nutrients. The pellets are easy to handle and apply, making them convenient for horticulturists. They can be used for potted plants, bedding plants, and landscape plants. Organic fertilizer pellets help maintain healthy plant growth, improve flower and fruit quality, and promote overall plant vigor.

Livestock and Poultry Farming

Livestock and poultry farmers can also benefit from organic fertilizer pelletizers. Manure from livestock and poultry can be processed into organic fertilizer pellets. These pellets can then be used to fertilize pastures, hay fields, and crop fields that are used to grow feed for the animals. Recycling manure into fertilizer pellets not only helps manage waste but also provides a valuable source of nutrients for agricultural production. This closed-loop system is environmentally friendly and can contribute to sustainable farming practices.

Benefits of Using Organic Fertilizer Pelletizers

Improved Nutrient Utilization

The granulated form of organic fertilizers produced by pelletizers allows for better nutrient utilization by plants. The slow-release nature of the pellets ensures that nutrients are released gradually over time, matching the growth requirements of plants. This reduces the risk of nutrient leaching and volatilization, resulting in more efficient use of nutrients and lower fertilizer costs in the long run.

Easier Handling and Storage

Organic fertilizer pellets are easier to handle and store compared to powder fertilizers. They are less dusty, which is beneficial for the health and safety of workers. Pellets can be easily transported, bagged, and stored without the risk of caking or clumping. This makes them more convenient for both producers and users.

Enhanced Product Quality

Pelletizers can produce organic fertilizer pellets with a consistent size, shape, and density. This results in a higher-quality product that is more appealing to consumers. The uniform appearance of the pellets also indicates a more homogeneous distribution of nutrients, which is important for reliable fertilization.

Environmental Friendliness

By promoting the use of organic fertilizers, organic fertilizer pelletizers contribute to environmental sustainability. Organic fertilizers help improve soil health, reduce the need for synthetic fertilizers, and minimize the negative impacts of agriculture on the environment. The granulation process also helps reduce the potential for nutrient runoff and air pollution associated with powder fertilizers.

Conclusion

The organic fertilizer pelletizer is an essential piece of equipment in the production of high-quality organic fertilizers. Its various working principles, types, and applications make it a versatile tool for different sectors, including agriculture, horticulture, and livestock farming. The benefits of using organic fertilizer pelletizers, such as improved nutrient utilization, easier handling, enhanced product quality, and environmental friendliness, highlight its importance in modern, sustainable agriculture. As the demand for organic fertilizers continues to grow, the development and use of advanced organic fertilizer pelletizers will play a crucial role in meeting this demand and ensuring the long-term health and productivity of our soils.