Fish feed extruders have actually ended up being a essential tool in the tank farming industry, permitting fish farmers to generate top quality feed that is tailored to the dietary needs of the fish they are elevating. With time, the design of fish feed extruders has progressed substantially, driven by advancements in technology and a expanding understanding of the requirements of the tank farming sector. In this essay, we will explore exactly how the layout of fish feed extruders has evolved in time.

The first fish feed extruders were reasonably simple machines, containing a screw conveyor and a barrel with a heating element. The screw conveyor would press the raw active ingredients via the barrel, where they would be warmed and also compressed, creating a consistent combination that could be formed into pellets or various other kinds. These very early makers worked however had actually restricted capabilities, and their layout was typically constrained by the technology of the moment.

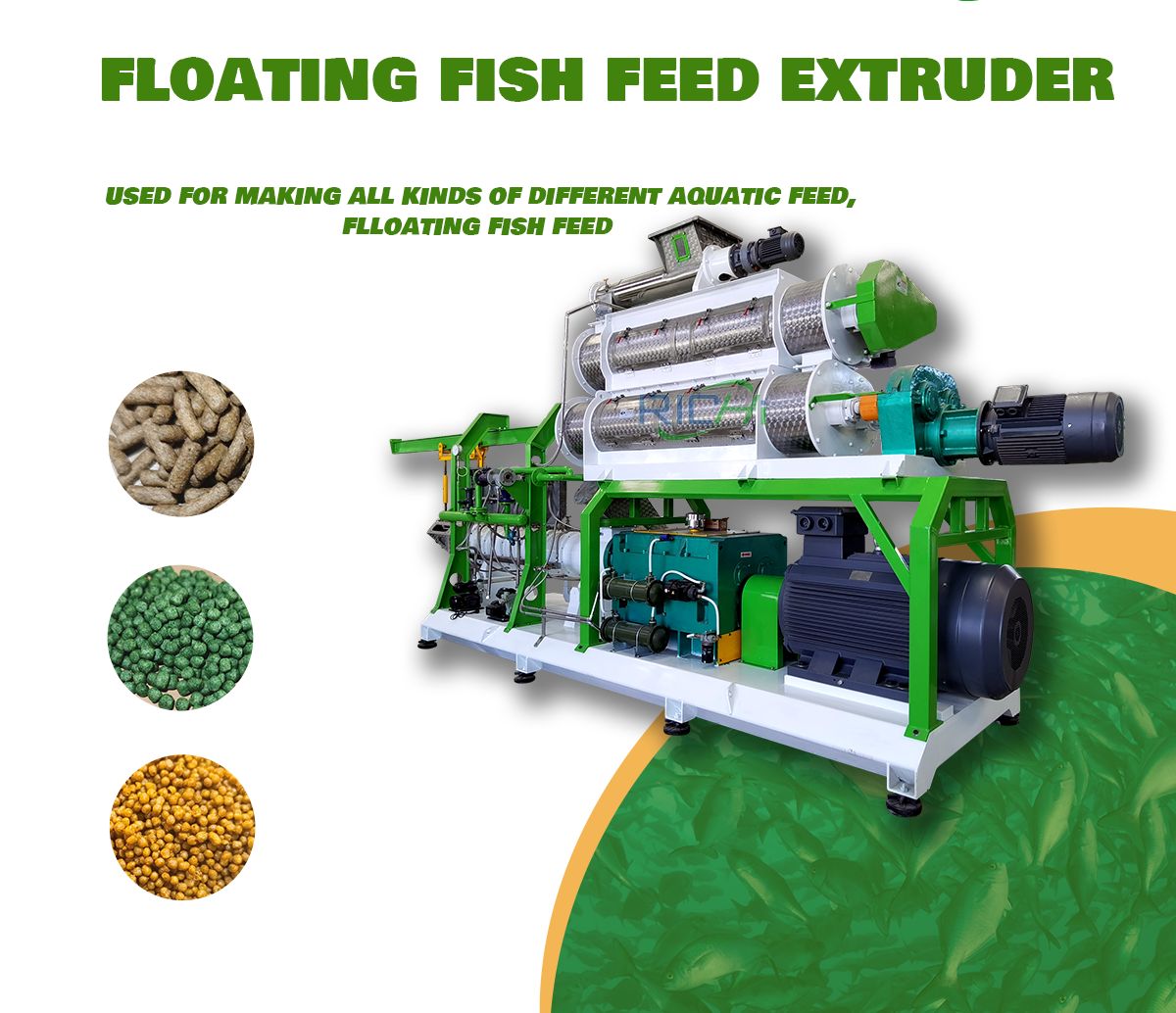

Related product: floating fish feed extruder machine

In time, developments in innovation and a expanding understanding of the requirements of the tank farming industry led to significant improvements in the design of fish feed extruders. One of the most essential developments was the intro of twin-screw extruders, which permitted greater versatility in the processing of different kinds of ingredients. Twin-screw extruders make use of two interlacing screws to move the raw products with the device, allowing for a lot more precise control over the extrusion procedure and also the capability to refine a wider variety of ingredients.

An additional vital growth in the style of fish feed extruders has actually been the introduction of innovative controls as well as checking systems. Modern fish feed extruders usually include sophisticated computer controls that permit drivers to readjust the speed, temperature level, and also various other criteria of the extrusion procedure in real-time. This allows for better accuracy as well as control over the manufacturing of fish feed, leading to better and more consistent results.

Along with these developments in technology, the design of fish feed extruders has additionally been influenced by an expanding awareness of the need for sustainable and ecologically liable manufacturing methods. Many modern fish feed extruders include functions that reduce waste and also minimize the environmental effect of tank farming procedures. For instance, some equipments make use of water-cooling systems that decrease power usage as well as reduce the quantity of water needed for the extrusion process.

Ultimately, the style of fish feed extruders has actually additionally been affected by the demand to satisfy the transforming needs of the tank farming industry. As the industry has expanded and also advanced, fish farmers have required equipments that are more functional, reliable, as well as reliable. This has brought about the advancement of fish feed extruders that can process a larger range of components, generate feed of differing sizes and shapes, as well as operate much more successfully and also dependably in a range of atmospheres.

Finally, the layout of fish feed extruders has actually developed dramatically with time, driven by advancements in modern technology, a expanding recognition of environmental concerns, and the altering needs of the aquaculture market. Today’s contemporary fish feed extruders are advanced devices that provide a series of capabilities and also functions, permitting fish farmers to produce top quality, healthy feed that is tailored to the demands of the fish they are increasing. As the aquaculture market continues to grow and also advance, we can anticipate to see additional breakthroughs in the style of fish feed extruders, assisting to make certain a sustainable as well as reliable source of fish and various other fish and shellfish for many years to come.

For more details,please visit RICHI on Facebook