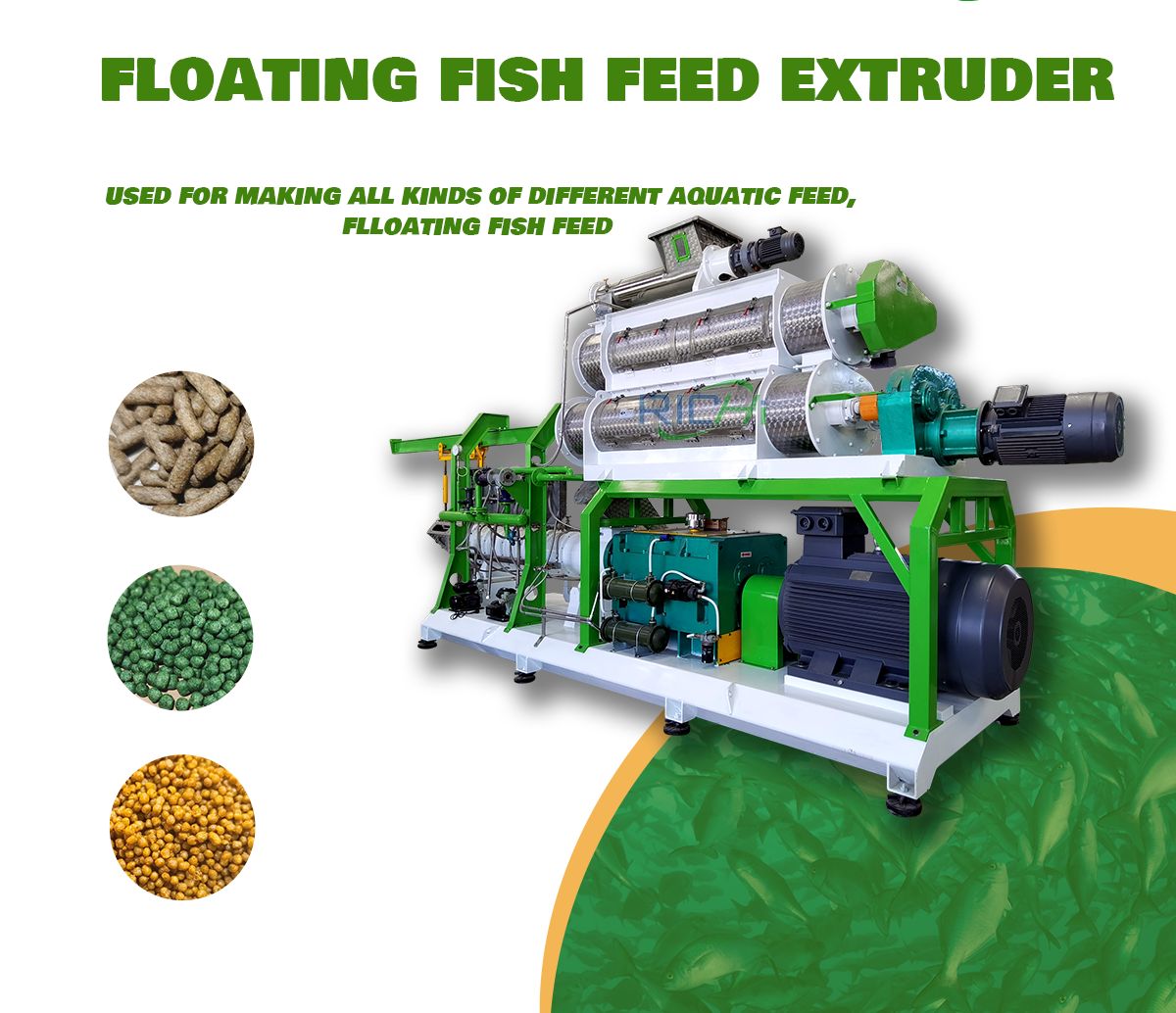

Fish feed extruder machine is a specialized piece of equipment designed to process as well as create high-grade fish feed. This equipment is used to generate floating fish pellets, which are a crucial resource of nourishment for farmed fish. In this essay, we will check out the various components of a fish feed extruder equipment and also how they work together to create high-grade fish feed.

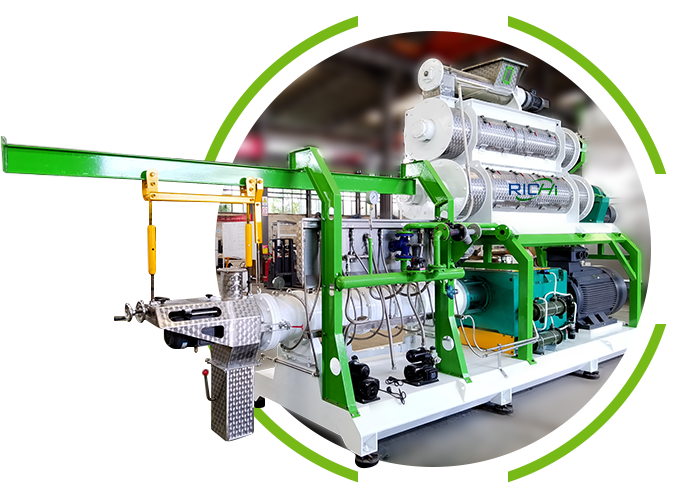

The components of a fish feed extruder equipment can vary depending on the details model as well as supplier. Nonetheless, the fundamental components include a feeder, a conditioner, an extruder, a clothes dryer, as well as a cooler. Allow’s take a closer look at each of these components.

The feeder is the initial component in the fish feed extruder machine. Its major function is to make sure that the raw products are regularly fed into the machine. The feeder can be a screw conveyor or a vibratory feeder. The option of the feeder will certainly depend on the kind and size of the raw products.

The next component in the fish feed extruder maker is the conditioner. This component is responsible for adding vapor and moisture to the raw materials. The heavy steam and also dampness help to soften the raw materials, making them less complicated to process in the extruder. The conditioner likewise adds crucial nutrients to the raw products.

The extruder is the heart of the fish feed extruder machine. It is responsible for refining the raw materials and also producing the fish feed pellets. The extruder consists of a barrel and a screw. The raw materials are fed into the barrel, where they are heated and pressurized. The screw then moves the raw materials through the barrel, compressing them as well as forming them into pellets. The shapes and size of the pellets can be readjusted by altering the extruder die.

After the fish feed pellets are created in the extruder, they are sent out to the dryer. The clothes dryer eliminates any staying moisture from the pellets. This is a vital action, as excess moisture can create the pellets to spoil. The dryer can be a conveyor clothes dryer, a fluidized bed dryer, or a rotating dryer.

The final component of the fish feed extruder machine is the cooler. The colder is accountable for cooling down the fish feed pellets after they have actually been dried out. The pellets are cooled to avoid them from breaking during transport as well as storage.

Now that we have actually examined the numerous components of a fish feed extruder machine allowed’s take a closer look at how they collaborate.

The process begins with the raw products being fed into the equipment with the feeder. The raw materials are after that conditioned in the conditioner, where heavy steam and also wetness are contributed to them. This softens the raw products and also adds important nutrients.

Next off, the raw products are fed right into the extruder. The extruder barrel heats and also pressurizes the raw materials, while the screw compresses as well as forms them right into pellets. The pellets are then sent to the clothes dryer, where any type of continuing to be moisture is eliminated. Ultimately, the pellets are cooled in the colder before being packaged and sent out to market.

Among the benefits of using a fish feed extruder equipment is the ability to create high-grade fish feed. The machine allows for exact control of the raw materials, making sure that the right equilibrium of nutrients is achieved. The extruder barrel and screw also give specific control over the size and shape of the pellets, causing consistent and consistent fish feed.

Finally, fish feed extruder machine is a specialized piece of equipment created to create premium fish feed. The equipment consists of a number of components, including a feeder, a conditioner, an extruder, a dryer, as well as a cooler. These components work together to process and create top notch fish feed pellets. The ability to create accurate as well as consistent fish feed is one of the main benefits of using a fish feed extruder machine.