Introduction

With the growing emphasis on renewable energy and sustainable resource management, sawdust has become an important raw material rather than an industrial by-product. As pelletized biomass gains popularity across residential, commercial, and industrial sectors, interest in pellet machinery has increased accordingly. Among the most frequently discussed topics in this field is sawdust pellet machine for sale, a term that reflects not only equipment cost but also technological complexity and market conditions.

Understanding pellet machine pricing requires a broader perspective that includes historical development, mechanical structure, production capacity, regional demand, and long-term operational considerations. This article presents an encyclopedic overview of sawdust pellet machine prices, focusing on the technical and economic factors that shape global markets.

Historical Context of Pellet Machine Development

Pelletization technology evolved from early briquetting methods used in Europe during the early industrial era. As sawmills expanded, sawdust disposal became a pressing issue, encouraging the development of densification machinery.

During the late 20th century, improvements in metallurgy, motor efficiency, and die manufacturing made pellet machines more reliable and cost-effective. These advancements directly influenced sawdust pellet machine price, as machines transitioned from simple mechanical devices to complex industrial systems with higher productivity and durability.

Definition of a Sawdust Pellet Machine

A sawdust pellet machine is an industrial device designed to compress fine wood residues into uniform cylindrical pellets. The pellets produced are widely used as biomass fuel and, in some cases, for non-energy applications such as animal bedding.

The machine functions by applying mechanical pressure and friction to sawdust, activating natural lignin as a binder. Pellet machines are commonly categorized by design type, capacity, and intended scale of operation, all of which influence pricing structures.

Key Structural Components and Their Cost Implications

Pelletizing Die and Roller System

The die and roller assembly is the most critical and wear-intensive part of a pellet machine. High-quality alloy steel dies with precision drilling significantly affect machine cost but also improve pellet consistency and service life.

Feeding and Conditioning Mechanism

Sawdust is lightweight and prone to bridging, requiring specialized feeding systems. Force-feeding designs and conditioning chambers add to the overall sawdust pellet machine price but enhance operational stability.

Drive System and Power Transmission

Motors, gearboxes, and couplings contribute substantially to machine cost. Energy-efficient motors and heavy-duty gear transmissions increase initial investment while reducing long-term energy consumption. https://richipelletizer.com/wood-pellet-mill-price/

Factors That Influence Sawdust Pellet Machine Price

Production Capacity

Machine output, typically measured in kilograms or tons per hour, is one of the primary pricing factors. Small-capacity machines designed for workshops differ significantly in cost from industrial-scale pellet presses.

Machine Design and Configuration

Ring die machines generally command higher prices than flat die models due to their higher output, durability, and suitability for continuous operation.

Material Quality and Manufacturing Standards

Machines manufactured with wear-resistant components and strict quality control standards tend to have higher upfront prices but offer longer service life and lower maintenance costs.

Level of Automation

Automation features such as intelligent control systems, temperature monitoring, and overload protection increase machine price but improve safety and efficiency.

Regional Variations in Pricing

The sawdust pellet machine price varies widely across regions due to differences in labor costs, manufacturing standards, and local demand.

In Europe, machines often meet stringent safety and environmental regulations, resulting in higher prices.

In Asia, a wide range of machines is available, from entry-level to industrial-grade equipment.

In North America, pricing reflects demand for high-capacity, durable machines suitable for large biomass operations.

Transportation costs, import duties, and after-sales support also influence regional pricing structures.

Relationship Between Price and Pellet Quality

Higher-priced pellet machines typically offer better control over compression ratio, die precision, and operating stability. These factors directly affect pellet density, durability, and combustion performance.

Operators focused solely on initial cost may encounter higher long-term expenses due to frequent maintenance or inconsistent pellet quality. As a result, sawdust pellet machine price is often evaluated in relation to lifecycle cost rather than purchase price alone. Click for source

Market Demand and Industry Applications

Demand for sawdust pellet machines is driven by multiple sectors, including renewable energy, forestry, and industrial manufacturing. Government incentives for biomass energy and carbon reduction policies have further increased market activity.

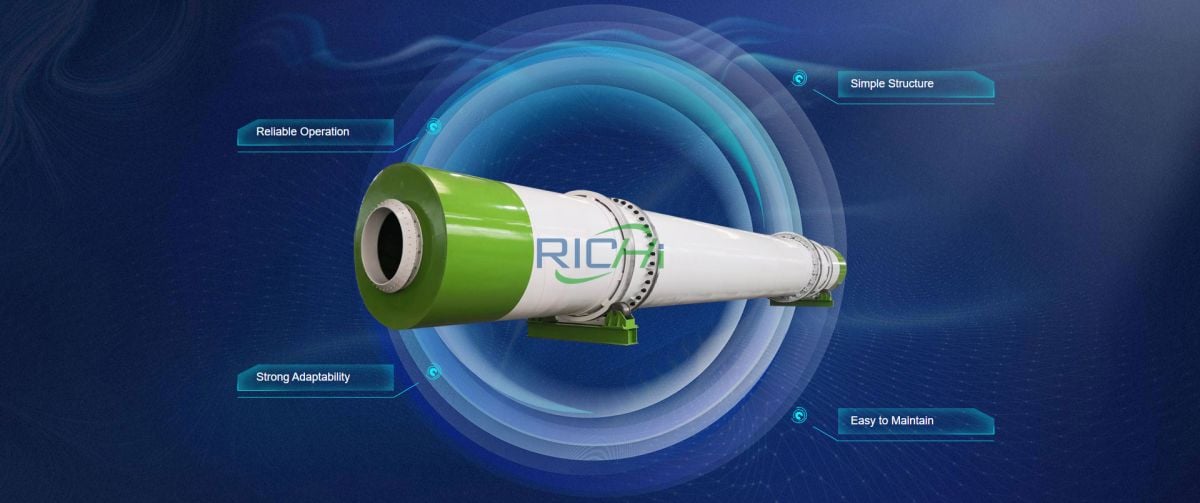

Manufacturers such as RICHI have participated in international pellet projects by supplying machines tailored to different production scales, contributing to broader market standardization.

Maintenance, Durability, and Total Cost of Ownership

The total cost of ownership extends beyond the initial machine price. Regular maintenance, spare parts availability, and technical support all influence long-term investment outcomes.

Machines built with standardized components and durable materials generally require fewer replacements and less downtime. Companies like RICHI Machinery emphasize structural strength and component compatibility to improve equipment longevity and cost efficiency.

Environmental and Economic Considerations

From an environmental perspective, pelletizing sawdust reduces industrial waste and supports renewable energy production. Economically, pellet machines enable value creation from materials that would otherwise be discarded.

When evaluating sawdust pellet machine price, operators often consider local sawdust availability, energy prices, and pellet market demand to determine financial feasibility.

Future Trends in Pellet Machine Pricing

Technological innovation continues to shape pellet machine pricing. Developments such as intelligent automation, energy-saving motors, and advanced die materials may increase initial prices while lowering operating costs.

As global biomass markets mature, price competition and technological standardization are expected to stabilize sawdust pellet machine prices over time.

Conclusion

The concept of sawdust pellet machine price encompasses more than the cost of equipment; it reflects technological capability, production efficiency, and long-term economic value. Understanding the factors that influence pricing allows buyers to make informed decisions aligned with operational goals and sustainability objectives.As renewable energy adoption continues to grow, sawdust pellet machines will remain a key technology in transforming wood waste into valuable biomass fuel. Sawdust pellet mill for sale canada