What is a Straw Pellet Mill?

A straw pellet mill is a specialized piece of equipment used to convert agricultural straw, such as wheat straw, rice straw, and corn stalks, into dense, cylindrical pellets. These pellets are primarily used as biofuel for heating, animal bedding, and as a feed supplement in livestock farming. The process involves grinding the straw, drying it to an optimal moisture content, and compressing it under high pressure to form pellets.

Uses of Straw Pellet Mill

Straw pellet mills serve various purposes across different industries:

- Biofuel Production: Straw pellets are a renewable energy source, often used in biomass power plants and heating systems. They have high calorific value and low ash content, making them an efficient and environmentally friendly alternative to fossil fuels.

- Animal Bedding: The high absorbency of straw pellets makes them ideal for use as bedding in livestock farming, particularly for horses, cattle, and poultry.

- Feed Supplement: In some cases, straw pellets are used as a roughage source in animal feed, providing fiber that aids in digestion for ruminants like cows and sheep.

- Industrial Applications: Straw pellets are also used in various industrial processes, such as in the production of biochar or as a raw material in the manufacturing of certain types of boards.

Market Analysis and Profit Point Analysis

The global market for straw pellet mills is experiencing significant growth due to the increasing demand for renewable energy sources and sustainable agricultural practices. According to market research, the biomass pellet market, which includes straw pellets, is projected to grow at a CAGR of 10.3% from 2023 to 2030, reaching a value of approximately $12 billion by 2030.

Key Market Drivers:

- Renewable Energy Demand: The push for cleaner energy sources is driving the adoption of biomass fuels, including straw pellets, particularly in Europe and North America.

- Agricultural Waste Utilization: The agricultural sector is increasingly looking for ways to manage and monetize waste, with straw pellet production providing a viable solution.

- Government Incentives: Subsidies and tax incentives for renewable energy projects are encouraging investment in straw pellet mills.

Profit Points:

- Cost Efficiency: Straw is often considered agricultural waste, meaning the raw material cost is low or even negligible, resulting in higher profit margins.

- Energy Savings: The energy required to produce straw pellets is relatively low compared to the energy they produce when burned, leading to significant cost savings.

- High Demand: The growing demand for sustainable products ensures a steady market for straw pellets, providing consistent revenue streams.

Classification, Working Principle, and Process Flow of Straw Pellet Mill

Classification:

Straw pellet mills can be classified based on their operating mechanisms:

- Flat Die Pellet Mill: Typically used for small to medium-scale production, this type is simple in design and operation, making it suitable for farmers and small businesses.

- Ring Die Pellet Mill: Ideal for large-scale production, this type is more efficient and produces higher quality pellets. It’s commonly used in commercial operations.

Working Principle:

The straw pellet mill operates on the principle of compression. The process involves the following steps:

- Grinding: The raw straw is first ground into smaller particles using a hammer mill or a similar grinding device.

- Drying: The ground straw is dried to reduce its moisture content to the optimal level, typically around 10-15%.

- Pelletizing: The dried straw is then fed into the pellet mill, where it is compressed through a die by rotating rollers. The high pressure causes the lignin in the straw to soften and bind the particles together, forming dense pellets.

- Cooling: The hot pellets are cooled to harden them and reduce the risk of moisture absorption during storage.

- Screening and Packaging: The pellets are screened to remove fines and then packaged for distribution.

Application in the Industry

Straw pellet mills are extensively used in:

- Biomass Power Plants: For the generation of electricity and heat from renewable sources.

- Agriculture: To produce bedding and feed supplements for livestock.

- Construction: In the production of eco-friendly building materials.

Case Studies and Supplier Selection

Case Study 1: A European Biomass Pellet Plant

A biomass pellet plant in Germany adopted a 5T/H straw pellet production line to meet the increasing demand for renewable energy. The plant chose a ring die pellet mill for its efficiency and capacity, resulting in a 20% reduction in operational costs and a 15% increase in energy output.

Case Study 2: A Livestock Farm in North America

A large-scale livestock farm in the United States implemented a 2T/H straw pellet production line to produce bedding material. The custom-designed line allowed for seamless integration into the farm’s operations, reducing bedding costs by 30% and improving the health of the animals.

How to Choose a Straw Pellet Mill and Its Suppliers

When selecting a straw pellet mill, consider the following factors:

- Production Capacity: Choose a mill that matches your production requirements. Flat die mills are suitable for small-scale operations, while ring die mills are better for large-scale production.

- Customization: Look for suppliers who can customize the production line to suit your specific needs, whether it’s integrating with existing systems or adjusting to different types of straw.

- Supplier Reputation: Select a supplier with a strong track record, reliable after-sales support, and the ability to provide turnkey solutions.

RICHI Machinery: A Leading Supplier

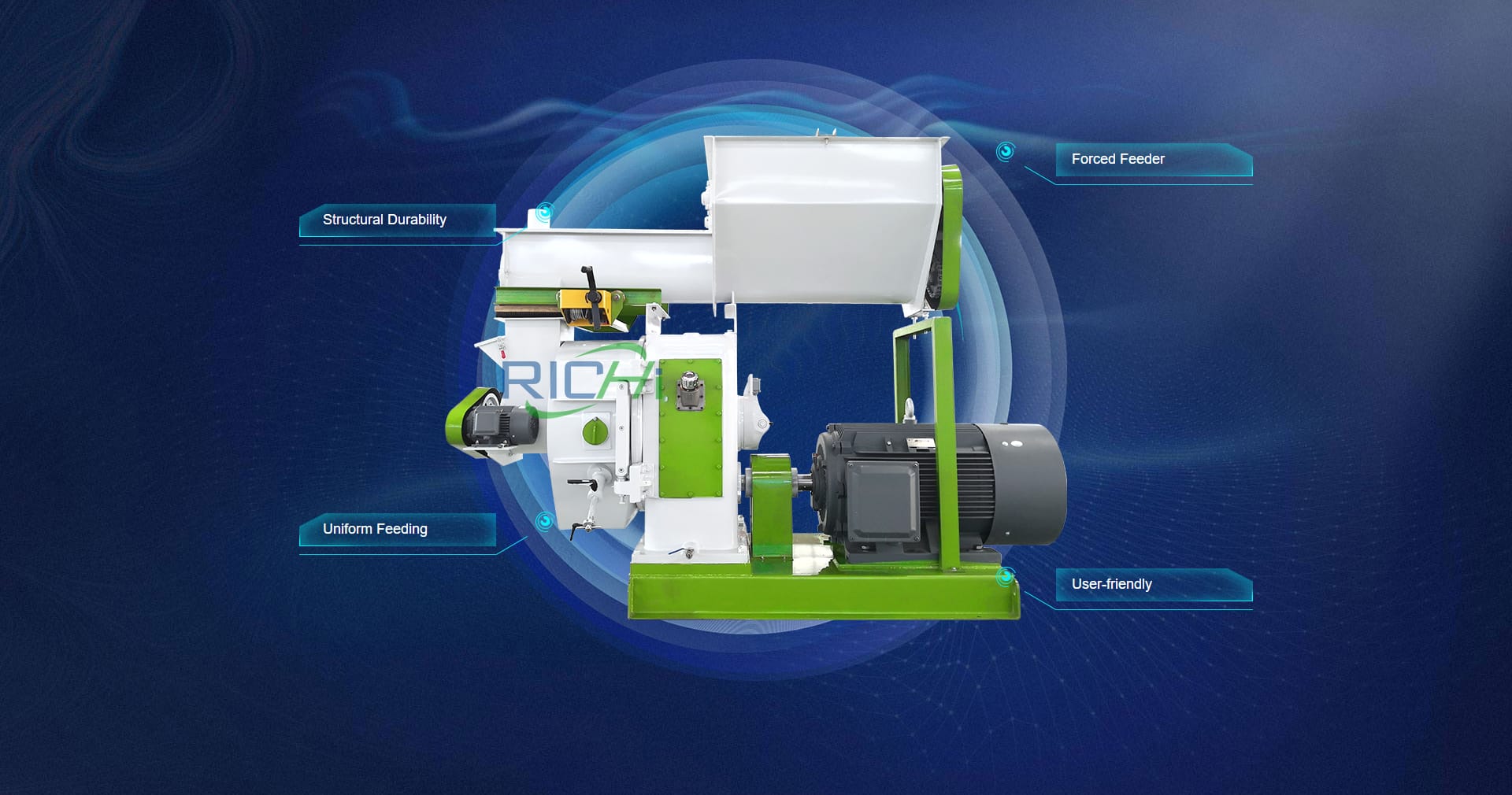

RICHI Machinery stands out as the most professional pellet mill manufacturer in China and the largest in Henan province. The company offers:

- Turnkey Solutions: RICHI provides complete project management from design to installation, ensuring seamless integration and operation of the production line.

- Customization: The ability to customize production lines to meet specific customer needs, from small-scale to large-scale operations.

- Advanced Technology: RICHI’s pellet mills are equipped with the latest technology, ensuring high efficiency, durability, and low operational costs.

- Comprehensive Support: With a focus on customer satisfaction, RICHI offers robust after-sales support, including maintenance services and technical assistance.

Summary

The necessity of choosing a straw pellet mill is clear: it transforms agricultural waste into valuable products, whether as a renewable energy source, animal bedding, or feed supplement. With the global push towards sustainability, the demand for straw pellets is set to rise. Selecting the right equipment and supplier, such as RICHI Machinery, ensures you can capitalize on this growing market efficiently and profitably.

Frequently Asked Questions (FAQs)

Q1: What is the ideal moisture content for straw before pelletizing? A: The ideal moisture content for straw before pelletizing is typically between 10-15%.

Q2: How do I choose between a flat die and a ring die pellet mill? A: Flat die pellet mills are suitable for small-scale production, while ring die pellet mills are more efficient and ideal for large-scale operations.

Q3: Can straw pellets be used for industrial applications? A: Yes, straw pellets are used in various industrial applications, including biochar production and as raw material in certain manufacturing processes.

Q4: What are the benefits of choosing RICHI Machinery for a straw pellet mill? A: RICHI Machinery offers turnkey solutions, advanced technology, customization options, and comprehensive after-sales support, making them a leading choice for straw pellet mills.

Q5: How can I ensure consistent pellet quality? A: Consistent pellet quality can be ensured by maintaining the correct moisture content, using high-quality equipment, and regularly calibrating the pellet mill.