Wood chip dryers are crucial in the wood processing and biomass industries, significantly aiding in reducing the moisture content of wood chips, sawdust, and other biomass materials. Their implementation can lead to substantial production cost reductions, enhancing operational efficiency and providing various economic advantages. This article delves into the key benefits of utilizing wood chip dryers to lower production costs.

1. Enhanced Energy Efficiency

Wood chip dryers are designed to improve energy efficiency in several ways:

- Optimized Drying Process: Modern wood chip dryers, like those from Biopellet Machine, ensure uniform and efficient drying, reducing the energy needed to achieve the desired moisture levels.

- Heat Recovery Systems: Many dryers feature heat recovery systems that capture and reuse heat from the exhaust air. This not only conserves energy but also reduces operational costs by lowering the need for additional fuel or electricity.

- Utilization of Biomass Fuel: Some dryers can use biomass fuel, such as wood chips or sawdust, to generate the required heat. This creates a closed-loop system that reduces reliance on external energy sources, thus lowering fuel expenses.

2. Increased Product Quality and Value

Proper drying of wood chips and sawdust enhances their quality, making them more valuable and versatile:

- Consistent Moisture Content: Uniform drying is essential for producing high-quality wood products like pellets and particleboard. Wood chip dryers ensure consistent moisture levels, leading to a more reliable and valuable final product.

- Higher Calorific Value: Dried wood chips and sawdust possess a higher calorific value, making them more efficient as biomass fuel. This increase in energy content also raises their market value, potentially leading to higher revenue.

- Reduced Spoilage and Waste: By minimizing the risk of mold growth and spoilage during storage, proper drying reduces waste and ensures more of the raw material is effectively utilized.

3. Reduced Transportation and Storage Costs

Drying wood chips and sawdust reduces their volume and weight, leading to savings in transportation and storage:

- Lower Transportation Costs: Decreasing the moisture content reduces the material’s weight, which in turn lowers transportation costs—a significant advantage for operations transporting wood chips over long distances.

- Efficient Storage: Dried wood chips and sawdust occupy less space, allowing for more efficient use of storage facilities. This can reduce the need for additional storage infrastructure, further lowering costs.

4. Improved Operational Efficiency

Implementing wood chip dryers enhances overall operational efficiency:

- Continuous Production: Modern wood chip dryers, such as those offered by Dorset Group, are designed for continuous operation, maximizing throughput and minimizing downtime.

- Automated Controls: Advanced control systems enable precise monitoring and adjustment of drying parameters, ensuring optimal performance with minimal manual intervention. This reduces labor costs and boosts operational efficiency.

- Versatility: Wood chip dryers are capable of processing various biomass materials, including sawdust and agricultural residues. This versatility allows producers to handle different materials without investing in multiple specialized machines, reducing capital expenditures. (Related post: Straw Dryer)

5. Environmental Benefits and Compliance

Wood chip dryers also contribute to environmental sustainability and regulatory compliance:

- Lower Emissions: Efficient drying processes result in reduced emissions of volatile organic compounds (VOCs) and other pollutants, helping producers comply with environmental regulations and avoid potential fines.

- Sustainable Practices: Utilizing biomass fuel and incorporating heat recovery systems in wood chip dryers supports sustainable production practices, enhancing a company’s environmental reputation and appeal to eco-conscious customers.

- Waste Reduction: Efficient drying maximizes the conversion of raw material into valuable products, aligning with circular economy principles and supporting sustainable resource management.

Case Study: Small-Scale Implementation

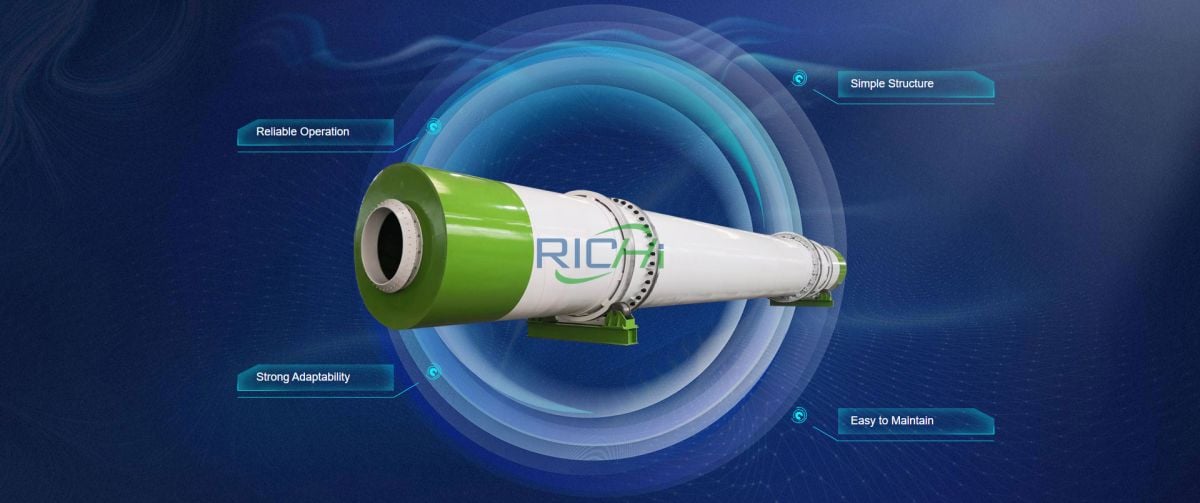

Consider a small sawmill processing 1-2 tons of sawdust daily. By implementing a compact wood chip dryer, such as the Ф0.8*10 model from RICHI Machinery, significant cost savings can be achieved:

- Energy Savings: Using a biomass-fueled dryer reduces reliance on external energy sources, lowering fuel costs.

- Increased Revenue: Dried sawdust can be sold at a higher price for uses like animal bedding or pellet production, generating additional income.

- Reduced Waste: Proper drying minimizes spoilage, ensuring more sawdust is effectively utilized.

Conclusion

Wood chip dryers offer numerous advantages in reducing production costs, making them a valuable investment for wood processing and biomass production operations. By enhancing energy efficiency, improving product quality, reducing transportation and storage costs, and streamlining operations, these dryers contribute to significant cost savings and operational efficiency.

For small-scale operations, the initial investment in a wood chip dryer can be offset by long-term benefits, including reduced energy costs, increased revenue from higher-quality products, and more efficient resource use. As technology advances, wood chip dryers are becoming more accessible and affordable, making them an increasingly attractive option for producers of all sizes.

By carefully selecting the appropriate dryer and considering factors such as energy source, integration with existing systems, and environmental impact, producers can maximize the benefits of wood chip dryers and achieve sustainable, cost-effective production processes.

For details please contact: Richi Pellet Mill

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com