The convergence of sustainable energy practices and efficient waste management has led many industries to explore innovative ways to repurpose their byproducts. In Portugal, where the furniture industry is a significant economic contributor, the question arises: Can a furniture factory build a 1-2 tons per hour (T/H) wood pellet production line in Portugal? This article explores the feasibility, challenges, and potential benefits of such a venture in the Portuguese context.

The Synergy Between Furniture Manufacturing and Wood Pellet Production

Furniture factories in Portugal generate substantial amounts of wood waste, including sawdust, wood shavings, and offcuts. Traditionally, this waste has been seen as a disposal challenge. However, with the growing demand for renewable energy sources, these byproducts can be transformed into valuable wood pellets. A 1-2 T/H wood pellet production line could offer a perfect solution for furniture factories to monetize their waste while contributing to sustainable energy practices.

Feasibility of Implementation

Several factors support the feasibility of implementing a wood pellet production line in Portuguese furniture factory:

- Raw Material Availability: Furniture factories have a consistent supply of wood waste, ensuring a steady input for pellet production.

- Existing Infrastructure: Many furniture factories already have some of the necessary infrastructure, such as storage areas and material handling equipment.

- Energy Efficiency: The production line can potentially use the factory’s existing power supply, optimizing energy consumption.

- Market Demand: Portugal, like many European countries, has a growing market for wood pellets, both for domestic heating and industrial use.

- Government Support: Portugal’s commitment to renewable energy may translate into incentives for such initiatives.

Related post:https://www.pellet-richi.com/news/20tph-biomass-pellet-plant-for-waste.html

Key Components of a 1-2 T/H Wood Pellet Production Line

To set up a wood pellet production line, a furniture factory would need to invest in the following key equipment:

- Wood Chipper: To reduce larger wood pieces to a manageable size.

- Hammer Mill: For grinding the wood chips into fine sawdust.

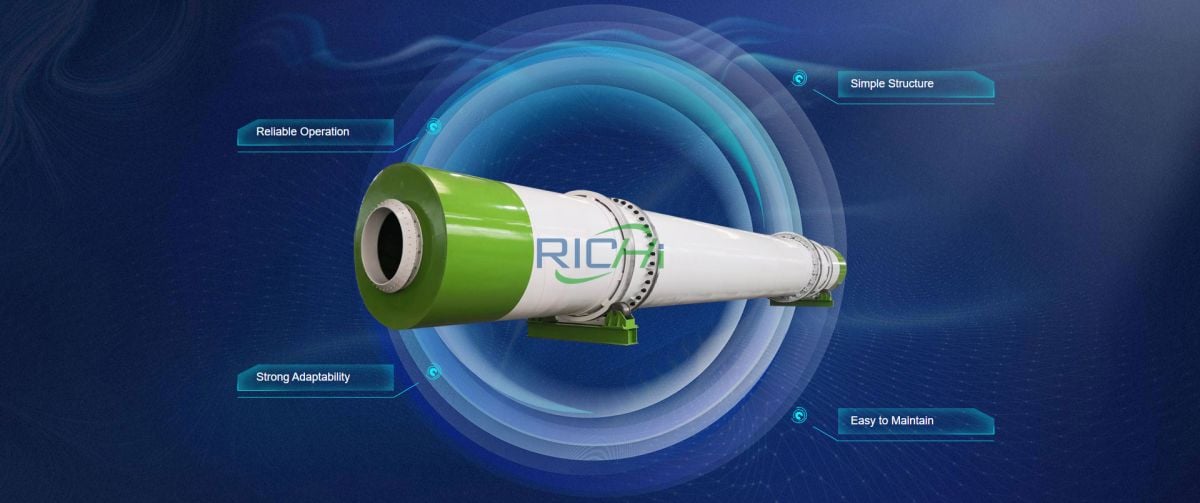

- Dryer: To reduce moisture content in the sawdust to optimal levels.

- Pellet Mill: The core machine that compresses the sawdust into pellets.

- Cooler: To cool down the hot pellets exiting the pellet mill.

- Screening System: To remove fine particles and ensure uniform pellet size.

- Packaging System: For bagging the finished pellets.

Challenges and Considerations

While the concept is promising, there are several challenges to consider:

- Initial Investment: The cost of setting up a 1-2 T/H production line can be significant, ranging from €200,000 to €500,000, depending on the level of automation and equipment quality.

- Space Requirements: A furniture factory needs to allocate sufficient space for the pellet production line, which might require reconfiguring the existing layout.

- Regulatory Compliance: Meeting environmental and safety regulations for both furniture manufacturing and pellet production can be complex.

- Quality Control: Ensuring consistent pellet quality while managing furniture production may require additional expertise and resources.

- Market Competition: The wood pellet market in Portugal is competitive, and entering as a new player might be challenging.

Benefits for Portuguese Furniture Factories

Despite the challenges, integrating a wood pellet production line offers several benefits:

- Waste Reduction: Significantly reduces waste disposal costs and environmental impact.

- Additional Revenue Stream: Creates a new income source from what was previously considered waste.

- Enhanced Sustainability Profile: Improves the company’s environmental credentials, potentially attracting eco-conscious customers.

- Energy Self-Sufficiency: The factory could use some of the produced pellets for its own heating needs, reducing energy costs.

- Contribution to Circular Economy: Aligns with Portugal’s and EU’s circular economy goals.

Case Study: Success in Similar Contexts

While specific examples from Portugal might be limited, there are success stories from other European countries. For instance, in Italy, several furniture manufacturers have successfully integrated small-scale pellet production lines, turning their waste into a profitable byproduct. These cases demonstrate the viability of such projects when properly planned and executed.

Steps for Implementation

For a Portuguese furniture factory considering this venture, the following steps are crucial:

- Feasibility Study: Conduct a thorough analysis of costs, potential returns, and market demand.

- Raw Material Assessment: Evaluate the quantity and quality of wood waste produced.

- Equipment Selection: Choose appropriate machinery that fits the factory’s scale and type of wood waste.

- Regulatory Compliance: Ensure all necessary permits and certifications are obtained.

- Staff Training: Invest in training employees to operate and maintain the pellet production line.

- Market Strategy: Develop a plan for selling the produced pellets, possibly partnering with existing distributors.

The Portuguese Context

Portugal’s commitment to renewable energy and its strong furniture manufacturing sector create a favorable environment for such initiatives. The country’s National Energy and Climate Plan (PNEC 2030) emphasizes the importance of biomass in achieving renewable energy targets. This policy framework could provide support and incentives for furniture factories venturing into wood pellet production.

Conclusion

The integration of a 1-2 T/H wood pellet production line into a Portuguese furniture factory is not only feasible but potentially highly beneficial. It offers a sustainable solution to waste management while creating a new revenue stream. However, success depends on careful planning, adequate investment, and a clear understanding of both the pellet market and production processes.

As Portugal continues to push towards a more sustainable and circular economy, initiatives like this could play a crucial role.

Furniture factories that take this step could position themselves as leaders in sustainable manufacturing, potentially gaining a competitive edge in an increasingly eco-conscious market.While challenges exist, the potential benefits in terms of waste reduction, additional revenue, and environmental impact make this an avenue worth exploring for Portuguese furniture manufacturers. With the right approach and support, the integration of wood pellet production into furniture manufacturing could become a model of industrial symbiosis and sustainable practice in Portugal and beyond.